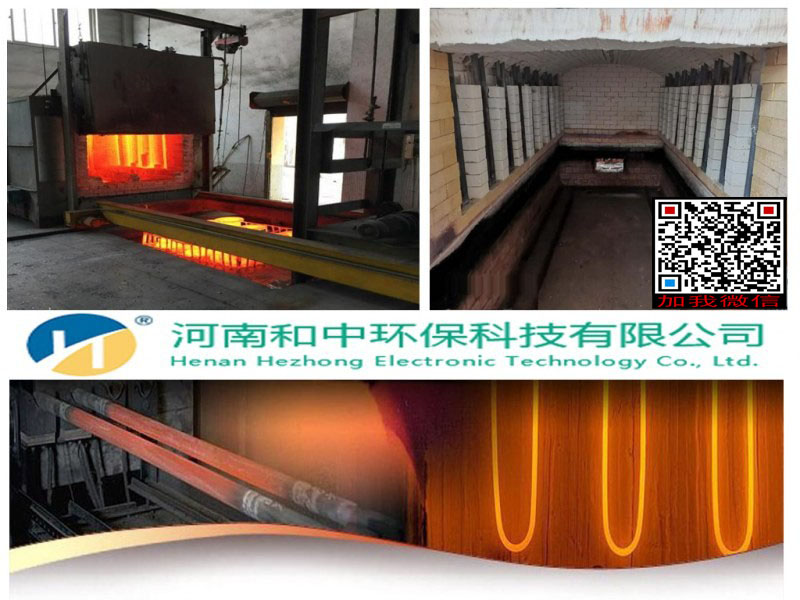

致力于碳化硅电热元件的生产

中国河南中岳碳化硅电热元件生产商

24小时咨询热线

13939069448

When we buy silicon carbide rods, in order not to affect the use of equipment, we need to test them to determine the advantages and disadvantages of silicon carbide rods. So how to detect it? Here are several feasible methods:

1. judge from the surface of silicon carbide rod:

从硅碳棒的材质来区别,设备一般都是选用高纯度的碳化硅为原料;从硅碳棒的尺寸和规格已经接口的焊接部分来判断;在硅碳棒的发热部测阻过程以及后续使用寿命等,都可以对比硅碳棒的好坏。

2、Tested by instrument:

(1)Through detailed recording of ammeter data and temperature control meter output percentage. When the furnace temperature is stable at a certain temperature, if the rod is broken, the output percentage of the instrument will increase compared with the previous time period, and the current displayed by the ammeter will decrease.

(2)Compare the current value of two groups of silicon carbide rods inside and outside the same temperature zone and the percentage of instrument output. Under the same output percentage, the internal resistance current should be close to half of the external group current.

(3)Compare different temperature zones. When the temperature is the same, compare the output percentage and current value of the temperature control meter. Compare the internal resistance with the internal group, and compare the external group with the external group. When the temperature control meter outputs the same percentage, the current should be basically the same. Observe the furnace to see if there is a black ring. If there is an obvious black ring, it is more likely to break the rod.

The above is about the detection method of whether there is abnormality in silicon carbide rod. Through different test methods, we can judge more accurately. If conditions permit, the two methods can be used together. If problems are found during detection, they should be solved in time, and they should be repaired or replaced according to the actual situation to avoid affecting the progress of production.

掰一下看容不容易断,摸一下看粉质粗吗,粉质细了才好

硅碳棒与电阻丝马弗炉有何区别?哪个好些?

硅碳棒优于电阻丝。材质不同,耐高温也不一样,硅碳棒可以达到更高的温度,所以现在一般的马弗炉用的都是硅碳棒了...

使用硅碳棒时应注意哪些?谢谢了?

你好,炬星窑炉为你解答1、硅碳棒性脆,强度很低,容易析断,所以,安装或更换时要十分小心。2、硅碳棒耐急冷急热...

硅碳棒是一种高温电子元件,如果使用或储存中由于存在操作失误导致其受潮等,就特别容易发生断棒现象。所以我们在使用硅碳棒之前为了不影响使用,我们可以实现对其进行检测来确定它的状态,进而判断硅碳棒还能不能继续使用。

1、详细记录电流表数据和温控表的输出百分比。当炉温稳定在某一温度时,如果存在断棒的情况发生,则仪表的输出百分比较前一时间段会加大,在电流表显示的电流会减小,也就是说可通过电流变化来判断它的状态。

2、对比同温区的内外两组电流值和仪表输出百分比。在同样输出百分比想比较的情况下,硅碳棒的内阻电流应接近于外组电流的一半,否则可能有问题。

3、不同温区做比较。温度相同时对比其温控表的输出百分比和电流值。将内阻和内组做比较、外组和外组做比较,如果在温控表相同百分比输出的情况下,电流应基本一致。除此之外还可以观测炉膛是否有黑环,若有明显黑环则断棒可能性比较大。如发现有异常情况则应及时采取相应措施。

以上就是关于硅碳棒是否存在异常的检测方法,通过不同的测试方法可以更加准确的判断,若发现问题就要及时解决,根据实际情况进行修复或者更换,避免影响生产的进行。